In past times, the global environment of manufacturing has undergone major transformations, prompting businesses to reconsider their approaches and locations for production. The country of China has long been the epicenter of manufacturing, attracting companies with its vast labor force and well-developed supply chains. However, as the dynamics of the global economy evolve, a growing number of firms are beginning to question the viability of this system. The need for agility, innovation in design and reaction to market needs has led numerous to explore options beyond China's.

The challenges associated with manufacturing in China are complex, including increasing wages, increasing governmental regulations, and geopolitical tensions that can interrupt supply chains. As firms strive to remain proactive, the push for change becomes more urgent. Shifting production away from the country not only addresses these critical concerns but also encourages a more decentralized and resilient model of manufacturing. By relocating manufacturing operations closer to target markets, companies can enhance their ability to create in product design while responding swiftly to consumer demands. This change could foster a new era of production that highlights adaptability and local production, ultimately aiding both companies and consumers around the world.

Current State of Production in China

China has long been acknowledged as the world's production center, serving as a pivotal focal point for manufacturing across various industries. move manufacturing out of china has built a resilient infrastructure that supports heavy production, attracting multinational corporations seeking cost-effective options for their operations. Despite its advantages, including a large labor force and established supply chains, the landscape of manufacturing in China is beginning to show signs of strain. Increasing labor costs, legal challenges, and concerns over standards are forcing companies to reassess their long-term strategies.

Furthermore, the ongoing geopolitical tensions and trade disputes have shaped China's manufacturing landscape. Companies face challenges that affect trade relations, particularly with significant partners like the United States. These challenges drive businesses to evaluate the risks involved in maintaining extensive operations within China. As a result, many organizations are considering diversification of their production locations to lessen these risks while ensuring supply chain resilience and stability.

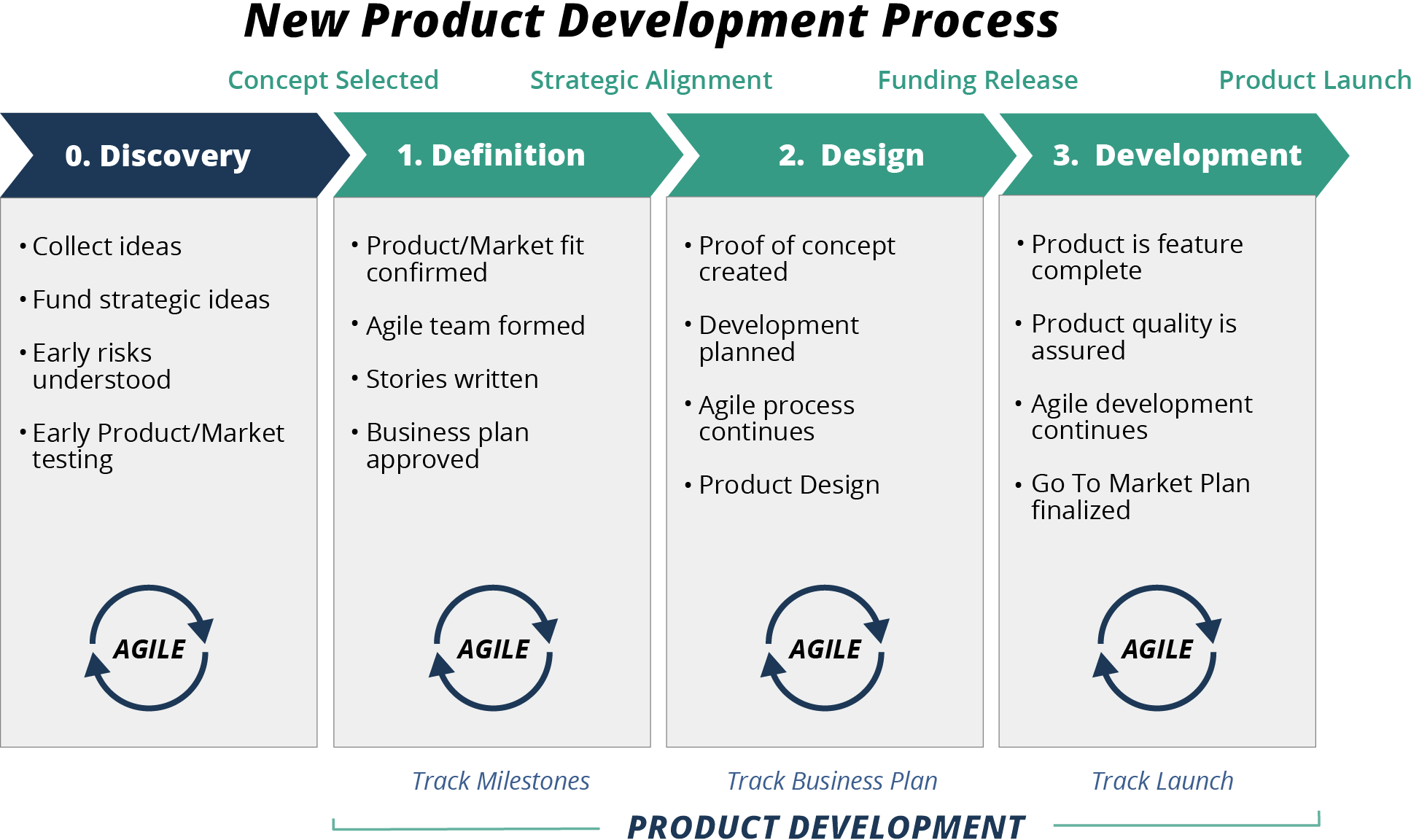

Moreover, the rising demand for creative solutions and agile product design is encouraging a shift in manufacturing strategies. As companies aim to bring innovative products to market quickly and respond to consumer preferences, they recognize the constraints of centralized manufacturing in China. The desire for enhanced flexibility in product design and manufacturing processes urges businesses to consider alternative locations where they can find cost, quality, and responsiveness to market needs. The current state of manufacturing in China thus presents both challenges and opportunities for a strategic reassessment of global supply chains.

Challenges in Design of Products

As firms reconsider their production methods, one significant hurdle emerges in the area of product design. When creating goods intended for production in China, firms often face challenges linked to the complicated aspects of the local manufacturing landscape. Inconsistency in material quality, production capabilities, and adherence to design specifications can lead to difficulties in realizing a consistent product vision. This uncertainty often forces designers to adjust on their original concepts to meet the realities of manufacturing.

Another aspect of complexity arises from the fast speed of technological change and evolving market demands. Designers must keep up with trends while also anticipating how changes in production capabilities can affect their designs. In a market where flexibility is essential, the dependence on a specific nation for manufacturing can stifle creativity and sensitivity to consumer needs. As companies grapple with these challenges, the question becomes whether the existing design processes are still effective in a landscape where manufacturing efficiency and speed to market are paramount.

In conclusion, the need for cooperation between designers and manufacturers is more essential than ever. Successful product design depends on effective communication and alignment of expectations throughout the development process. As firms evaluate alternatives to Chinese manufacturing, nurturing partnerships with manufacturers capable of maintaining the integrity of the design while offering adaptability and efficiency will be vital. This change could enable designers to focus on creativity and functionality, paving the way for new products that meet evolving consumer preferences.

Innovative Strategies for Upcoming Development

As businesses evaluate moving production out of the country, innovative solutions must be prioritized to ensure sustainable growth. Utilizing advanced technologies such as automation and artificial intelligence can optimize manufacturing processes and reduce dependency on conventional labor. By investing in smart manufacturing systems, organizations can improve productivity, elevate product quality, and reduce lead times, making them more successful in the international market.

Collaboration with local innovators in new regions can also lead to advancements in product design and manufacturing. By establishing partnerships with new ventures and research institutions, organizations can tap into new ideas and unconventional approaches. This exchange of knowledge not only accelerates the development of new products but also integrates sustainable practices into the manufacturing process, aligning with growing consumer demand for eco-friendly solutions.

Finally, investing in supply chain diversification will be crucial. By establishing manufacturing in various countries, businesses can mitigate risks associated with political tensions, regulatory changes, and labor issues in any specific region. This calculated move not only boosts resilience but also allows for site-specific production, enabling companies to tailor products more closely to regional markets, thus driving growth through more effective alignment with consumer preferences.